Manufacturing depends on shipping and packaging to deliver final products safely and undamaged. The widely accepted method for shipping products is by pallet where items to be shipped are placed on a plastic or wood slatted platform and secured. As simple as the process may sound, it is one of the most vital elements for a company’s success. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

U.S. Packaging & Wrapping LLC. is a National leader in flexible packaging solutions. Find a large variety of packaging machinery for bundling, securing, and protecting products. Learn information about industrial, retail, and food packaging machines. Shop online today or call 1-800-441-5090 for assistance!

At Cleveland Equipment & Machinery Company, we take pride in being a trusted provider of high-quality packaging equipment designed to meet the needs of businesses of all sizes. We specialize in offering a wide range of machinery to streamline packaging processes, from entry-level solutions to advanced equipment for high-volume operations.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

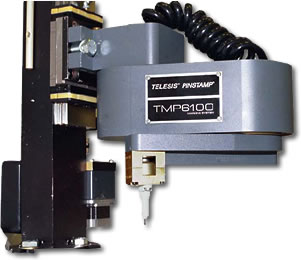

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services