Strapping material and tools are used with stretch wrap to secure boxes and pallets for shipment. Strapping machines are mechanical devices used to enhance the process of wrapping pallets or products with reinforcing cables made of plastic or similar material to prevent the product from splitting apart or falling apart during transit. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

BILWINCO works closely with companies to develop and design packaging equipment. We manufacture, deliver and install all machinery, as well as perform preventative maintenance and system optimization. Filling machines, packaging machinery, weighers and more for the food and hardware industries.

More Strapping Machine Manufacturers

These machines can be of various sizes and types- ranging from fully manual, handheld tools to fully automated, labor-free strapping instruments. In addition, workers can use manual handheld or battery-powered hand-operated machines on a factory or warehouse floor. The benefit here is that these hand-operated machines are extremely portable. An arch-less strapping machine, meanwhile, can be easily integrated into any product assembly structure. Arched strapping machines, on the other hand, can handle larger products at speeds of up to 60 straps per minute and can also be placed near an assembly line. In addition, these machines are completely automated, reducing the time required to prepare the product for shipping or storage.

Types of Strapping Machines:

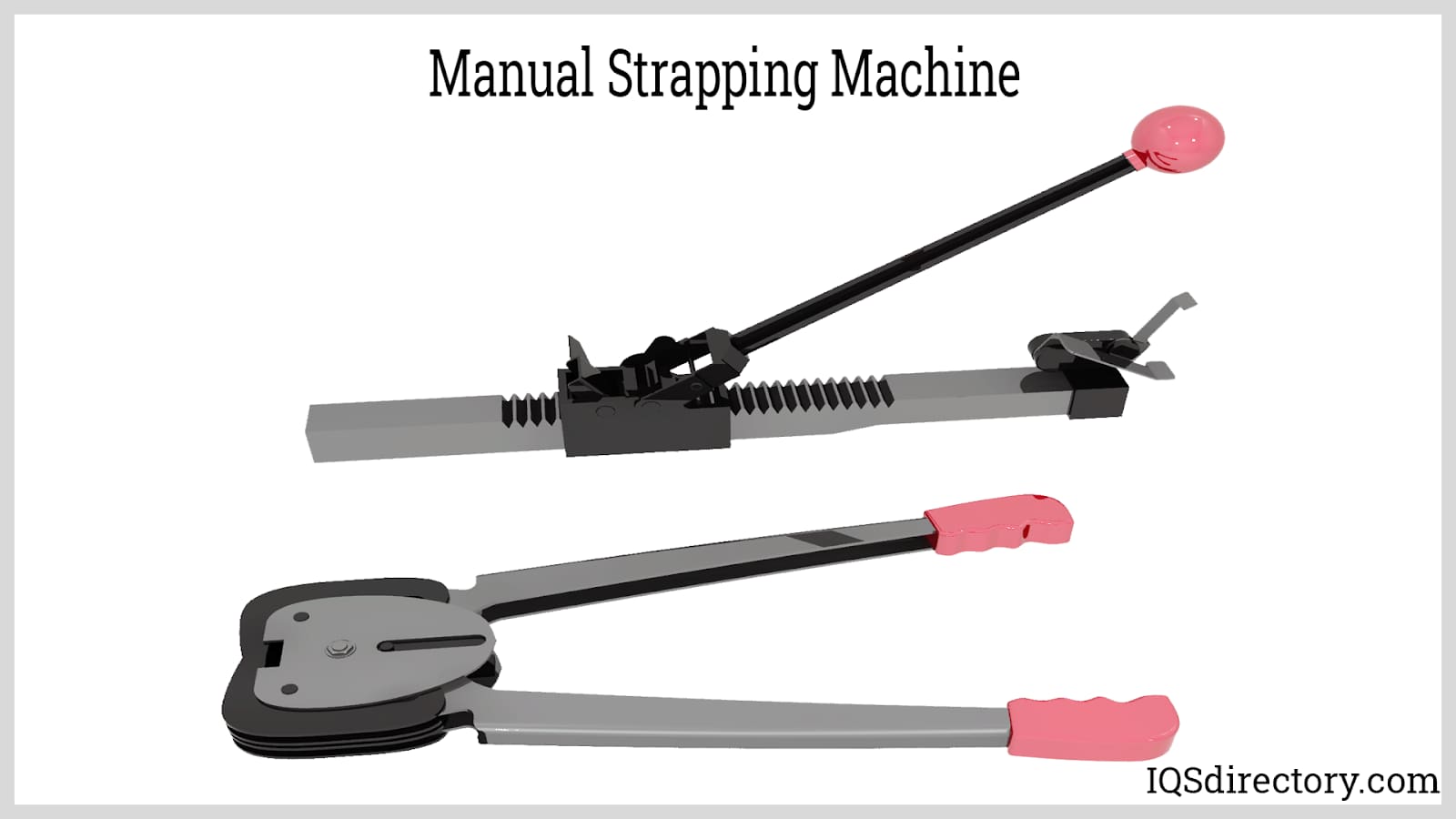

Manual Strapping Machine

Manual strapping machines are suitable for a wide variety of packaging. These strapping machines are mobile, versatile, and can be used on both the vertical and horizontal axis. These devices are suitable for small to medium companies with lower strapping rates and can be used to strap goods at either fixed or mobile workstations.

Automatic Strapping Machine

Automatic strapping machines utilize sensors to follow a target item or box through a conveyor line before starting the strapping process. The machine is fed strap material via a spool or pulley system. The material is rotated around the target by mechanical spinners or arms. Workers can incorporate this mechanical, swift motion into an assembly line. These machines have the benefit of not requiring an operator. However, Designers must calculate the containers' dimensions to receive the straps properly. When figuring production rates, it is critical to realize they have a maximum strapping output of 60 per minute. Their price is high and varies depending on the features and dimensions of the machine. Simple to operate, automatic strapping machines only require that the item be placed in the arch and a button or removable pedal be pressed to process it.

Strapping Table Machine

A strapping table is a semi-automatic strapping machine. The operator must position the goods, press a button to begin the strapping process, and remove the goods once the cycle is complete for the strapping tables to function properly. These machines are basic and suitable for low-volume work. Typically, they are about the size of a small desk. To operate a strapping table machine, an employee takes a strap that the machine has already extended, wraps it around the package, and then manually inserts it into the area for strapping and any required adjustments. The machine automatically secures the ends, tightens the strap to a predetermined tension, and provides a predetermined strap length for the following cycle. The main benefit of this type of strapping device is that it doesn't matter what size the items need to be strapped. Unlike automatic models, the amount of strapping that can be done on a strapping table is limitless because this kind of machine doesn't first need to produce an arch or loop of strapping around the goods before securing them.

Types of Strapping Material:

Polypropylene

For the strapping of relatively light shipments or pallets, polypropylene (PP) strapping tape is a highly affordable option. Its key benefit is that it is adaptable and thus simple to utilize. Additionally, it has excellent resistance to rust and temperature changes. It can be used as a temporary means to protect delicate things, stop the theft of priceless items, or store commodities. It can be unwound manually, electrically, or with another device.

Extruded Polyester

PET (polyester) strapping tape is ideal for compressible weights like wood, cardboard, and some building materials, as well as for relatively large loads (up to 550 kg/1,212 lb or even 1,000 kg/2,204 lb depending on the type). This material successfully shields packaged items from a collision on the road because of its extremely high strength and flexibility. This material also enables safe and simple handling. It can tolerate a maximum temperature of 80°C/176°F and is resistant to moisture and UV rays. In addition, it doesn't rust or change shape. As a result, this material is appropriate for the long-term storage of commodities. In addition, polyester straps can be tightened manually, mechanically, or electrically.

Metal

Since iron and concrete do not compress and create large and inflexible loads with sharp or rough edges, metal straps are the best choice for securing loads of such materials. In addition, metal straps don't bend like other types of straps do. These sturdy straps can be securely fastened with or without joints and are appropriate for heavy loads up to 2,000 kg (4,409 lb).

Choosing the Proper Strapping Machine Supplier

To ensure the most beneficial outcome when purchasing a strapping machine from a strapping machine supplier, it is important to compare several companies using our directory of strapping machine suppliers. Each strapping machine supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each strapping machine business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple strapping machine companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

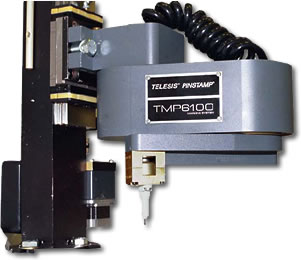

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services