Pallets are a form of material handling and movement equipment that have been a part of industrial operations for nearly 100 years. Originally made of wood, they have been modernized and improved to meet the needs of modern manufacturing. The placement of products and items on pallets was once a manual process performed by workers at the end of a production line, but has been improved over the years to be more efficient. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

BILWINCO works closely with companies to develop and design packaging equipment. We manufacture, deliver and install all machinery, as well as perform preventative maintenance and system optimization. Filling machines, packaging machinery, weighers and more for the food and hardware industries.

More Palletizer Manufacturers

As with many of the processes of manufacturing, the method of loading pallets has been automated by palletizers, which automatically sort, transfer, and stack products, or goods. The development of palletizers was a necessary innovation to meet the needs of high-volume production.

What is a Palletizer?

Automated palletizers provide load stability, convenience, and faster load movement. The process of manually placing boxes and materials on pallets was time consuming, costly, and inefficient. Manual labor became incapable of meeting the needs of high-volume production and produced undo stress on workers.

The development of the palletizer has improved productivity and enhanced material handling while efficiently and effectively loading finished products onto pallets. The process of the palletizer requires a connection with the assembly process, which involves a conveying system of rollers or belts.

As products come down the conveying system, the palletizer picks up the items with a crane, scoop, arm, or other form of mechanism and places them on a pallet. For the process to function smoothly, the items to be loaded may be required to be of a uniform shape and size though advanced robotic systems are capable of handling incongruous shapes and configurations.

Each item is neatly stacked on the pallet accounting for weight, size, and item configuration. Once the pallet is full, it is electronically wrapped and removed to make room for the next load.

Types of Palletizers

There are several factors that are used to group and categorize palletizers. Though the function of each type is similar, the methods used to accomplish their function varies according to the products, items, and packaging of the items to be loaded. One method of grouping palletizers is by their location and level of automation. Classifications include robotic, low and high level, and in-line.

Robotic palletizers can be automatic or semi-automatic and are placed between a pallet dispenser and the conveying system. The placing of the items is accomplished by a hydraulic robotic arm that lifts the load and places it on the pallet. The difference between low and high level palletizers is the location where they receive the load. With low level, the load is received on the ground with the load for high level being received above the ground. Either type can be automated or semi-automated depending on the needs of the process.

In-line palletizers receive a complete load before shifting it to the pallet. A row of the product comes down the conveying system and is collected. Once the line is full, the row is shifted to the pallet to make room for the next row. This can also be achieved with suction cups that collect items as they arrive and hold them until they have a full load.

Benefits of Palletizers

The central concern of industrial operations is speed and efficiency, which can provide the ability to manufacture and move products in a short amount of time. The introduction of palletizing has significantly improved the time and effectiveness of production methods, adding an important step forward for industrial operations.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

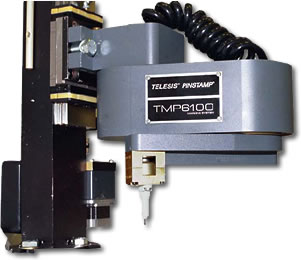

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services