One of the necessities of production, sales, inventory, and supply chain development is the ability to easily identify items in the system so that they can be located. An essential factor in the process is labeling items, or materials, with distinct markings that describe their location, purpose, and other pertinent data. The process of labeling began centuries ago with marks being handwritten to distinguish one item from another or as means of specifying the owner. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

BILWINCO works closely with companies to develop and design packaging equipment. We manufacture, deliver and install all machinery, as well as perform preventative maintenance and system optimization. Filling machines, packaging machinery, weighers and more for the food and hardware industries.

More Marking Machinery Manufacturers

As the marking process developed, written labels were created, which were followed by printed labels that have evolved into the present-day bar codes. The introduction of bar coding has rapidly advanced and improved the various marking machinery methods to the point that an extraordinary amount of data and information can be stored on marking labels.

What is Marking Machinery?

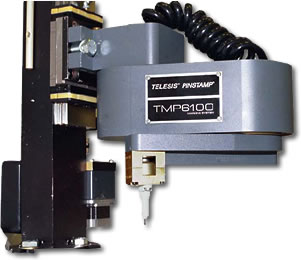

Marking machinery covers an industry that engineers and designs methods for labeling a wide range of items and materials such that they can be easily located. As economic concerns have grown, producers and manufacturers have worked with marking machinery producers to develop methods that can precisely and concisely identify every machine, component, and device that is a part of a company’s inventory.

The importance of accurate data is of major emphasis by financial officers when they answer for the allocation of funds. The main reason for these systems is to provide a means for controlling inventory and accounting for assets. Marking methods have been developed to fit the needs of every industry from small items for children to large, enormous presses.

The type and kind of system depends on what is being labeled and how permanent the label needs to be. Production equipment requires metal, unalterable labels that describe their function and process. Trucks and transport equipment are labeled as a means of locating them and what they are transporting.

How Marking Machinery Works

For many years, the marking process was simply placing a ticket or label on merchandise or equipment. In many cases, the data on the label was at the discretion of the person preparing the label, which varied drastically from company to company and person to person. With the beginning of inventory taxation, methods for organizing, storing, and identifying inventory needed to be more precise and accurate, which led to the rapid improvement in the marking machinery industry.

The former method of sticking a label on an item has grown and developed into a wide array of methods that provide concise data instantly. Though this has been necessitated by economics, it has also become a means for improving the profitability and performance of companies.

The present marking machinery produces identifiers in several varieties, few of which include stick on labels. The computerization of the process has led to the development of labels that can precisely identify an item from how it is made to where it is located. Financial officers can oversee inventory movement through the data processing system as warehouse workers scan the labels on materials as they are handled.

The Importance of Marking Machinery

Methods of marking items and materials have transformed into a technical industry capable of instantly providing data regarding the status of a company’s inventory. Though it grew from various economic issues, its perfection and development has led to a means for controlling costs, identifying assets, and increasing profits.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services