Packaging machinery is used for packaging products. Using packaging machinery can save costs for manufacturers. Packaging machinery can quickly and efficiently pack products that would otherwise need to be packaged manually (which is more expensive and less effective). Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

BILWINCO works closely with companies to develop and design packaging equipment. We manufacture, deliver and install all machinery, as well as perform preventative maintenance and system optimization. Filling machines, packaging machinery, weighers and more for the food and hardware industries.

More Packaging Machinery Manufacturers

Types of Packaging Machines

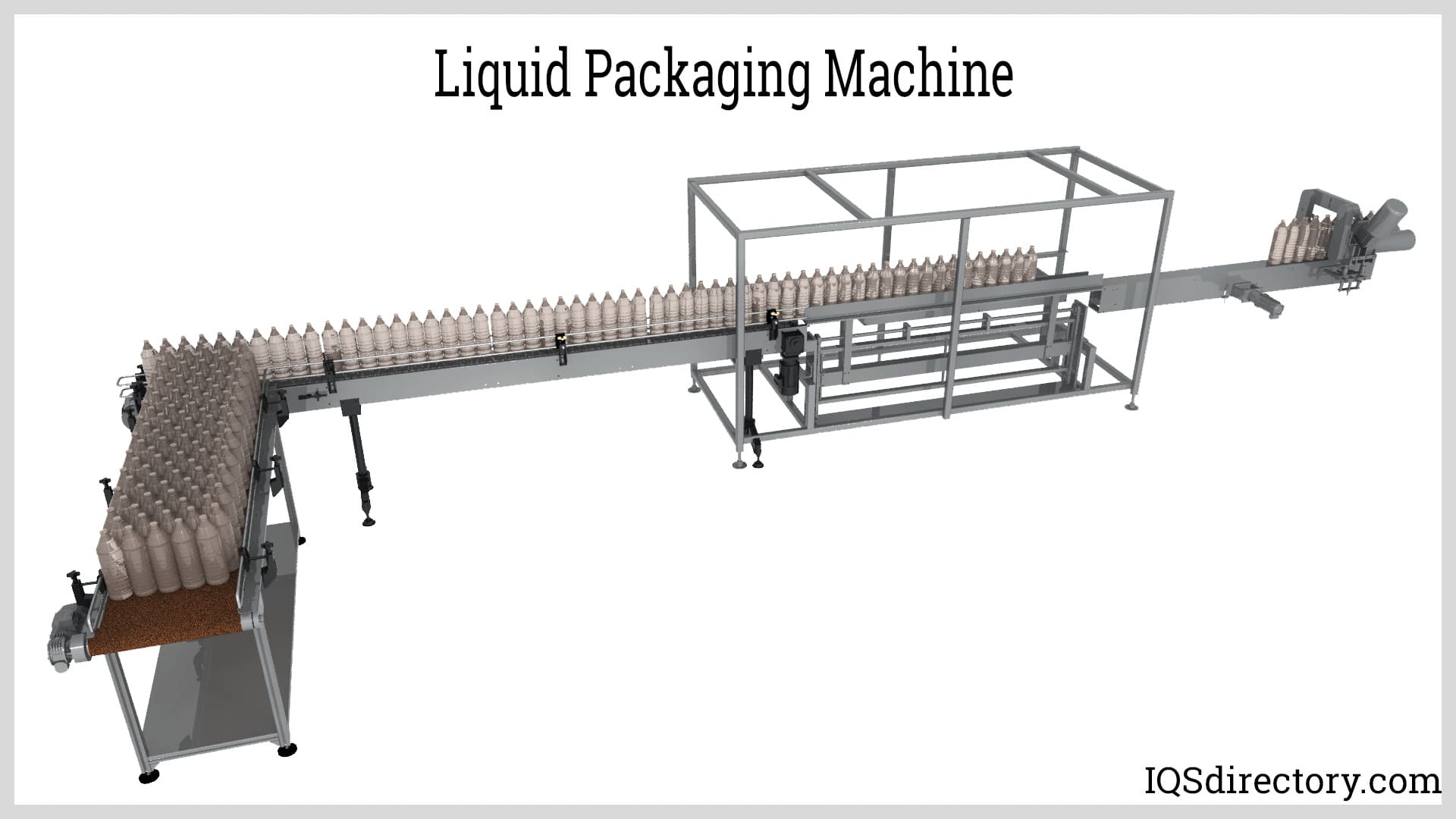

Packaging machines work faster than manual labor. Standard packaging equipment includes shrink wrappers, filling equipment, heat sealers, labeling equipment, and bagging equipment. There are several automated packaging procedures. For instance, vacuum packaging entails purging the oxygen from a container before sealing it. This procedure is frequently applied in food packaging to keep products from spoiling before consumer consumption. Conveyor belts are often used with packaging machinery to transfer products between various packaging stages.

Packaging Machinery

Blister Packaging Machine

Blister packaging machines pack tablets, capsules, and other unit-dose medications. They have a bubble pack component (a cavity or pocket made of a formable film) made of thermoformed plastic or cold-formed aluminum film. This often has an aluminum foil lidding closure.

Carded Packaging Equipment

Carded packaging equipment will package goods in a plastic container supported by a blister card or another plastic item. The three types of carded packing are clamshells, skin packs, and blister packs. Clamshells are fully made of plastic shells that close like their shellfish namesake, while skin packs and blister packs feature plastic shells integrated with blister board backers.

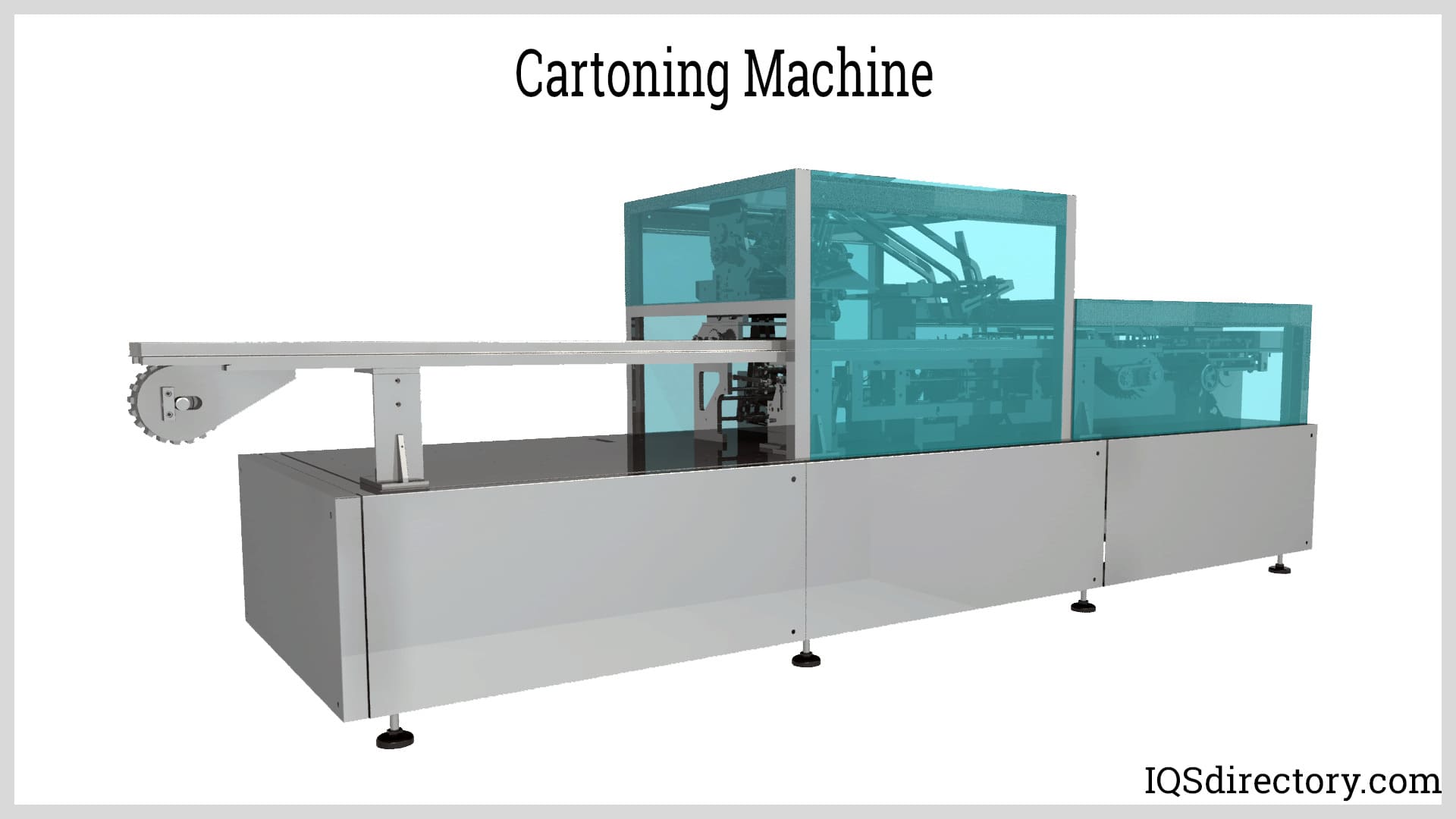

Cartoning machine

A cartoning machine (or a cartoner) produces closed, folded, erect, sealed, and side-seamed cartons. They turn carton board blanks into cartons filled with items, bags of products, or multiple products into a single carton following the filling process. Then the machine engages its slots to glue and cover both ends of the carton, effectively sealing it.

Case Erector

Case erectors will unfold or erect cardboard boxes to place products inside. This machine comes in manual, automatic, and semi-automatic varieties. A person must unfold, fold, or tape the box flaps into the form on manual machinery before handing the box to the following worker or placing it on a conveyor. Case erectors have a conveyor system that moves the box through areas that force it into the precise shape. Then, the constructed box is moved to a pile. Finally, an automatic case erector pulls a box out of the stack, unfolds it, and places it on an automatic conveyor system using mechanical components like a robotic arm. After passing through the conveyor system, the box is filled with the products and sealed.

Vertical Form Fill Sealing Machine

Automatic assembly line packaging systems and vertical form fill sealing equipment are used in the food packaging business. The machine uses a flat film roll to create plastic bags and stand-up pouches, which are then concurrently filled with goods and sealed. This packaging technique allows both liquids and solids to be bagged. Next, a continuous roll of flat plastic film that has labeling and artwork on the interior or exterior is loaded into the machinery. Vertical form-fill sealing machines also work with metalized paper, film/foil, and fabric.

Skin Packing Devices

Despite the similarities between blister packs and skin packs, the manufacturing processes for the two are extremely different. First, a platform on skin pack equipment is used to support the blister board or backing substrate. Then, the board is covered with the goods that need to be wrapped.

The device covers the products with a heated soft plastic layer that takes on the product's shape. The use of vacuum sealing frequently results in a tight fit. The substrate then adheres to the cardboard's heat-seal layer.

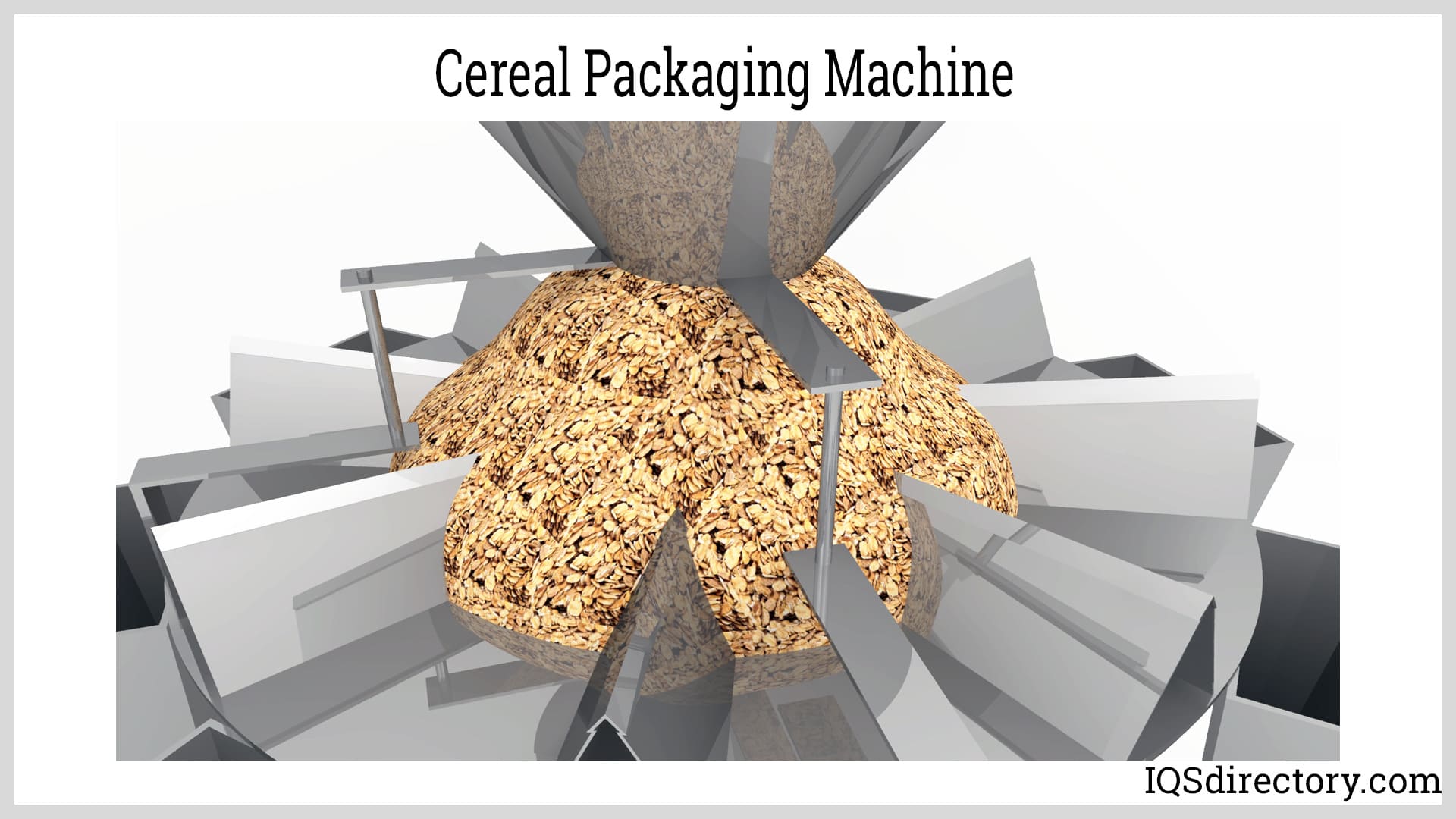

Applications of Packaging Machinery

Before products exit production lines, packaging technology is used to fill, pack, wrap, and bag the goods. These machines have replaced many time-consuming, hard chores previously completed by hand. As a result, packaging equipment is used in a wide range of sectors, especially those that manufacture or distribute small items in large quantities. For instance, manufacturers of breakfast cereals must have access to machinery that can package their goods swiftly and effectively.

Benefits of Packaging Machinery

Such products would be time-consuming and impractical to package manually. Additionally, automated equipment is greatly preferred over hand packing because many of these products are wrapped in heat-sealed bags to preserve the products' cleanliness and freshness. Workers must fill, seal, and move packaged products quickly enough to be financially viable in most high-volume production lines. Packaging machines save money throughout the entire packaging process. Machinery can reduce worker amenities, machine guard costs, and time spent packing each product.

Choosing the Right Packaging Machinery Manufacturer

To ensure you have the most productive outcome when purchasing packaging machinery from a packaging machinery manufacturer, it is important to compare several companies using our directory of packaging machinery manufacturers. Each packaging machinery manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each packaging machinery business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple packaging machinery companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services