A filling machine is a device that is extensively used in the production process of various industries. Filling machines are used to measure and pack liquid, powder, granular, or paste products into pouches, bags, and containers like bins and bottles. Different types of filling equipment using various mechanical techniques are available to accurately and quickly fill containers with an array of substances and products. For many businesses, the use of such packaging machinery increases productivity and lowers labor expenses. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

U.S. Packaging & Wrapping LLC. is a National leader in flexible packaging solutions. Find a large variety of packaging machinery for bundling, securing, and protecting products. Learn information about industrial, retail, and food packaging machines. Shop online today or call 1-800-441-5090 for assistance!

At Cleveland Equipment & Machinery Company, we take pride in being a trusted provider of high-quality packaging equipment designed to meet the needs of businesses of all sizes. We specialize in offering a wide range of machinery to streamline packaging processes, from entry-level solutions to advanced equipment for high-volume operations.

More Filling Machinery Manufacturers

Filling Machines: An In-Depth Guide to Types, Applications, and Selection

Filling machines are essential components in modern manufacturing and packaging operations, automating the precise measurement and dispensing of a wide variety of products into bottles, jars, vials, drums, and other containers. Whether you operate in the food and beverage, pharmaceutical, cosmetic, chemical, or hardware industries, investing in the right automatic or semi-automatic filling machine can dramatically improve throughput, accuracy, and product consistency while reducing manual labor costs and product waste. This comprehensive guide explores the various types of filling equipment, their core applications, and key considerations for selecting the best filling machine for your production line.

What Are Filling Machines and Why Are They Important?

Filling machines, also known as fillers or filling systems, are automated or semi-automated devices designed to dispense a predetermined amount of liquid, powder, granular, or solid product into a container. These machines are integral to a wide range of industries, including food packaging, beverage bottling, pharmaceutical filling, chemical dispensing, cosmetic production, and even the distribution of small hardware parts. By automating the filling process, companies can achieve higher levels of efficiency, uniformity, and hygiene—all critical for meeting industry regulations and consumer expectations.

Industrial Applications and Use Cases

Filling equipment is indispensable across diverse sectors. For instance, businesses that manufacture plastics rely on bulk filling machines to efficiently package and palletize plastic pellets for distribution. Manufacturers of small industrial hardware, such as screws, nuts, and bolts, use counting and weighing filling systems to pack their products into retail-ready containers for hardware stores. In the food industry, high-speed liquid fillers are used to bottle sauces, oils, and beverages, ensuring each package is filled to specification. The pharmaceutical sector depends on sterile, high-precision filling systems to safely dose medicines, vaccines, and tinctures into vials and syringes. Cosmetics companies use volumetric and piston fillers to package creams, lotions, and gels with consistent accuracy. Chemical manufacturers utilize filling machinery to handle corrosive or hazardous substances, prioritizing operator safety and regulatory compliance. If you're wondering, "What type of filling machine is best for my product or process?"—read on for a detailed breakdown of available technologies.

Types of Filling Machines

Pump Filling Machine

Pump filling machines, also known as pump fillers, are engineered to transport even the thickest materials, including viscous liquids that drip, stretch, or contain particulates. These versatile filling systems are ideal for both low and high-viscosity products, handling everything from watery solutions to dense substances like honey, car wax, salsa, or cosmetic creams. Operators can easily switch between different fill volumes and container sizes, making pump fillers particularly suitable for production lines with varied product SKUs. Pump filling machines are widely used in food processing, cosmetics, chemical manufacturing, and specialty product industries where flexibility and adaptability are paramount.

Common Applications of Pump Filling Machines

- Filling viscous food products (e.g., honey, jams, sauces, mayonnaise)

- Packing personal care items (e.g., shampoos, conditioners, lotions, gels)

- Dispensing automotive products (e.g., motor oils, waxes, lubricants)

- Handling chemical products (e.g., detergents, cleaning agents, adhesives)

Overflow Filling Machine

Overflow filling machines are designed for rapid, accurate filling of bottles and containers with thin to medium-viscosity liquids. This filling technology ensures that each bottle is filled to the same visual level, which is especially valuable for clear packaging where aesthetics and uniformity matter. Any excess product is automatically recirculated back into the storage tank, minimizing waste and promoting sustainable production. Overflow fillers are a popular choice for bottling water, juices, spirits, and other beverages, as well as liquid soaps and cleaning solutions. Their even fill level helps brands maintain a professional appearance on store shelves, reinforcing consumer trust and satisfaction.

Key Benefits of Overflow Filling Machines

- Consistent fill levels for high shelf appeal

- Minimization of product waste through recirculation

- Ideal for transparent bottles and containers

- Quick changeover between different bottle sizes and shapes

Gravity Filling Machine

Gravity filling machines utilize the force of gravity to channel free-flowing, low-viscosity liquids from a holding tank into bottles or containers positioned below. This simple yet effective technique is best suited for water, juices, wine, spirits, and other non-viscous products that do not contain particulates. Gravity fillers are cost-effective, easy to operate, and offer consistent volumetric fills using a timed dispensing approach. While commonly used in beverage bottling, gravity filling machines also find applications in the chemical, personal care, and specialty food sectors. Are you looking for a reliable way to fill water, oils, or other thin liquids with minimal maintenance? Gravity filling systems may be the perfect fit.

Gravity Filling Machine Advantages

- Low operating costs and simple design

- Ideal for non-carbonated, particle-free liquids

- Scalable from manual bench-top units to fully automated bottling lines

- Suitable for small-batch runs and large-scale production

Piston Filling Machine

Piston filling machines employ a volumetric piston mechanism to accurately dispense products ranging from thin liquids to thick creams and even semi-solid mixtures. These machines can handle products with suspended particles, such as fruit chunks in jams or particulates in sauces, making them highly versatile for challenging applications. Piston fillers draw product from a bulk tank—using either direct draw, buffer tank, or recirculation—and deposit precise amounts into each container, ensuring minimal waste and maximum dosing accuracy. This makes them especially well-suited for pharmaceuticals, nutraceuticals, CBD and THC tinctures, high-value essential oils, and food products where exact dosing is critical. Considering a piston filling solution? Contact leading piston filler manufacturers for tailored recommendations.

Piston Filler Use Cases

- Pharmaceutical liquid and semi-solid packaging

- Cosmetic creams, gels, and ointments

- Food products with particulates (salsas, chutneys, yogurt with fruit)

- Precise dosing of high-value or sensitive liquids

Other Filling Machine Types and Related Equipment

In addition to the core filling machine types described above, there are several specialized machines designed for specific materials or industries:

- Auger Filling Machines: Best for powders, spices, and granular products such as flour, sugar, and coffee.

- Tube Filling Machines: Used for filling ointments, gels, pastes, and creams into tubes for the pharmaceutical and cosmetics industries.

- Vacuum Filling Machines: Employed for filling delicate or foamy liquids, such as perfumes, ensuring a drip-free, bubble-free finish.

- Counting and Weighing Fillers: Ideal for small parts packaging, such as hardware (nuts, bolts, screws), or pharmaceutical tablets and capsules.

- Net Weight Fillers: Ensure each container receives an exact weight of product, commonly used for bulk food, chemicals, and industrial products.

How to Choose the Right Filling Machine for Your Application

Finding the optimal filling machine for your specific needs involves careful evaluation of several critical factors. This section outlines the main considerations to guide your equipment selection process, helping you answer common search questions like, "Which filling machine is best for thick liquids?" or "How do I choose a bottle filling machine for food products?"

- Viscosity of Product: Assess whether your product is thin, medium, or highly viscous. Viscous liquids often require pump or piston fillers, while thin liquids are suited to gravity or overflow fillers.

- Container Material & Shape: Consider the types of bottles, jars, tubes, or drums you use. Fragile or flexible containers may need specialized handling, while glass or rigid plastics can be filled with standard conveyors.

- Container Size & Fill Volume: Determine the range of container sizes and the necessary fill accuracy. Small vials for pharmaceuticals demand different technology than bulk drums for chemicals.

- Product Sensitivity & Cleanliness: Some products require sanitary or aseptic filling environments, especially in food, beverage, and pharmaceutical applications. Look for machines with easy-clean, stainless steel construction and, if needed, cleanroom compatibility.

- Filling Speed & Production Volume: Analyze your throughput requirements. High-speed rotary fillers may be necessary for large-scale bottling, while semi-automatic machines are sufficient for limited runs or startups.

- Integration with Existing Packaging Lines: Ensure compatibility with conveyors, capping machines, labeling systems, and other automated packaging equipment. Full line integration streamlines workflow and boosts efficiency.

- Filling Accuracy & Waste Minimization: Especially important for expensive or regulated products. Seek out filling solutions with advanced controls, sensors, and feedback systems to maintain tight tolerances and reduce overfill/underfill.

- Regulatory & Safety Compliance: Confirm your filling equipment can meet FDA, GMP, or other industry-specific standards—vital for pharmaceuticals, food, and hazardous chemicals.

- Budget & Total Cost of Ownership: Factor in not just the initial purchase price but also long-term maintenance, energy consumption, changeover times, and spare parts availability.

Filling Machine Benefits: Why Automate Your Filling Process?

Upgrading to automated or semi-automated filling machinery offers numerous advantages for manufacturers and packagers:

- Increased Efficiency: Dramatically speed up the filling process, allowing higher production volumes and faster time-to-market.

- Improved Product Consistency: Ensure each package contains the exact intended amount, boosting customer satisfaction and brand reputation.

- Reduced Labor Costs: Minimize manual intervention, freeing staff for higher-value tasks and reducing workplace injuries.

- Enhanced Cleanliness & Hygiene: Closed, automated systems minimize contamination risk—critical in food, beverage, and pharmaceutical environments.

- Lower Product Waste: Accurate dosing and recirculation features reduce spillage, overfill, and underfill, protecting your bottom line.

- Scalability: Modular filling equipment can be expanded or upgraded as your business grows or new products are introduced.

- Data Collection & Traceability: Modern fillers may integrate with plant management software, enabling real-time monitoring, batch tracking, and quality assurance.

Key Questions When Evaluating Filling Machine Suppliers

Choosing a filling machine supplier or manufacturer is a crucial step in ensuring long-term success. Here are some essential questions and action prompts to guide your research:

- What experience does the manufacturer have with your product type and industry?

- Can the supplier provide case studies or references for similar applications?

- Does the filling equipment offer flexibility for future product or packaging changes?

- What kind of technical support, training, and after-sales service is offered?

- Are spare parts and consumables readily available?

- Is custom engineering or turnkey line integration available if needed?

- What warranty and maintenance options are included?

Cost Considerations: How Much Does a Filling Machine Cost?

The price of filling machines varies widely based on factors such as type (manual, semi-automatic, fully automatic), production speed, filling technology, customization, and integration requirements. Entry-level benchtop fillers may start around a few thousand dollars, while high-capacity, fully automated rotary systems can reach six figures. When budgeting, consider not only the initial equipment investment but also installation, operator training, ongoing maintenance, and potential upgrades. To get an accurate quote, contact multiple filling machine manufacturers with detailed information about your product, containers, desired throughput, and any unique requirements.

Filling Machine Maintenance and Operational Best Practices

Proper maintenance is vital for maximizing uptime and longevity of your filling equipment. Follow these best practices to ensure reliable operation:

- Establish a routine cleaning and sanitization schedule, especially for food, beverage, and pharmaceutical lines.

- Regularly inspect wear parts, seals, and gaskets for signs of damage or fatigue.

- Keep spare parts inventory on hand to minimize downtime during repairs.

- Train operators on machine settings, troubleshooting, and safe operation.

- Work with your supplier to schedule preventative maintenance and software updates.

- Document and track performance metrics for continuous improvement.

Filling Machine Design Considerations

- Viscous Liquids: Selecting a suitable liquid filling machine hinges on the viscosity of your product. High-viscosity solutions may require heated lines, special pump designs, or agitation to prevent clogging and ensure smooth flow.

- Packaging Materials: The type of packaging—glass, PET, HDPE, flexible pouches, or metal cans—impacts the filler choice. Consider stability, compatibility with the filling method, and conveyor system requirements.

- Package Size: Container size dictates filler configuration, nozzle design, and the need for multi-head models to maintain line speed across various SKUs.

- Integration with Other Machines: Seamless communication between your filler, capping machine, labeler, and conveyor maximizes overall packaging line efficiency and reduces bottlenecks.

- Filling Accuracy: Evaluate the required dosing precision for your product. Industries like pharmaceuticals and high-value cosmetics often demand advanced dispensing controls and in-line weight verification systems.

Choosing the Proper Filling Machine Manufacturer

To ensure you achieve the best results when purchasing a filling machine, it's crucial to compare multiple suppliers. Use our comprehensive directory of filling machine manufacturers to review business profiles, explore each company's technical expertise, and identify specialists in your product category. Each listing offers direct contact forms for requesting additional information or a custom quote. Leverage our proprietary website previewer to quickly assess manufacturer offerings, then use our streamlined RFQ tool to contact multiple filling equipment suppliers simultaneously. By taking a methodical approach, you can secure the ideal filling machine for your specific needs, budget, and future growth plans.

Explore Further: Frequently Asked Filling Machine Questions

- How do I automate bottle filling for my small business?

- What is the best liquid filling machine for thick sauces?

- How do I reduce waste and improve accuracy in packaging lines?

- Are there filling machines for powders and granules?

- How can I integrate a filling machine with my current capping and labeling systems?

- What are the energy and maintenance requirements for automated filling equipment?

- Do I need a custom filling solution for my unique product?

If you have a specific application or technical challenge, contact our filling machine experts for personalized assistance and recommendations.

Conclusion: Unlocking Efficiency and Quality with the Right Filling Machine

Whether you're filling beverages, pharmaceuticals, chemicals, cosmetics, or hardware, choosing the right filling machine is essential for maximizing productivity, product quality, and profitability. By understanding the different types of filling equipment, their applications, and the key selection criteria, you can make an informed investment that supports your business goals. Explore our resources, compare top filling machine manufacturers, and take the next step toward automating your packaging process today.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

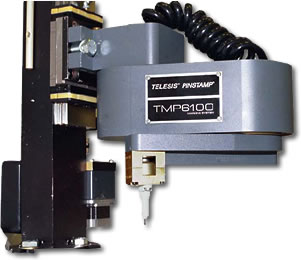

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services