One of the essential aspects of inventory control and supply chain management is the clear labeling of products, machinery, and materials. The purpose of identifiers is to provide the location and description of controlled items for ease of access. Computerization has streamlined the labeling process, increasing its efficiency and accuracy, a major factor in inventory control. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

At LPM Systems, we specialize in delivering high-quality packaging machinery tailored to meet the diverse needs of our customers. With years of industry expertise, we take pride in providing innovative, reliable, and efficient packaging solutions designed to optimize productivity and ensure consistent performance.

At Andy Pac, Inc., we specialize in delivering high-quality packaging machinery that meets the evolving needs of industries across various sectors. With a strong commitment to innovation, we design and manufacture equipment that enhances productivity, efficiency, and reliability in packaging operations. Our solutions are built to handle the demands of modern production lines, providing seamless...

More Labeling Machinery Manufacturers

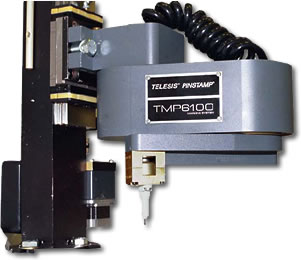

A labeling machine is a technically engineered device that produces labels, markings, symbols, and identifiers. These can easily and precisely be printed and applied to items, products, containers, machines, equipment, and packages. Labeling machinery is a generic term that is applied to a wide range of machines that have been specifically designed to assist in the labeling, marking, and identification process.

What is Labeling Machinery?

Labeling machinery comes in many varieties of sizes, types, configurations, and capabilities. The type of machine is dependent on the items or pieces to be marked and labeled as well as where the label will be placed. Regardless of the wide range of types of marking devices, the basic principle for all labeling machinery is the same, which is to produce a form of marking to identify an item or product.

The basic functionality of labeling machinery is to provide concise information that can be easily read and identifiable. For some industries, the information may be a set of numbers that include information regarding size, capacity, color, and other identifying abilities. In processes where more detailed information is required, labeling machinery may include short phrases that include color, size, or function.

The types of data and information available is constantly changing as manufacturers improve their processes and methods. Many of the changes regarding labeling technology is dependent on the rapid implementation of computerization and programming.

Types of Labeling Machinery

The types and kinds of labeling systems are dependent on convenience, items, mobility, type of label, accuracy of information, and purpose for labeling. For some operations, labeling and identifying of products, or parts, is required as a function of the production process. This aspect of labeling is enhanced and expanded when items are received at a customer location.

The easiest method for identifying labeling machinery is to divide them according to their size and purpose. The three main categories are handheld, tabletop, and integrated, with integrated being the most complex and handheld being the simplest. Each of the different designs have been developed to fit a specific need or requirement.

Though handheld may seem to be the simplest type of marking mechanism, recent advancements, such as the creation of programmable handheld devices that are linked to a computer system, have updated their capabilities. The classic form of labels produced by a handheld labeler are tied to or adhered to items. With the advent of bar codes, there is little need to apply labels since the bar code can be read for information by a handheld labeler.

Bench top labeling machinery comes in a wide assortment of types and designs, with dot peening being the most aggressive form. The basic tabletop, or bench top, labeling system can serve multiple functions such as identifying a manufacturer’s information or placing a permanent label by peening or engraving.

Integrated labeling systems are incorporated into the manufacturing process as a means of identifying items being assembled and produced. Labeling during production is a quick and efficient method for identifying items as they leave assembly operations.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services