Shrink wrapping is a process that involves the use of temperature-sensitive films to securely package products for shipping and storage, or to firmly seal items into individual units for sale. When an item is placed into the machine, the film contracts tightly to the object it is covering when heat is applied. The use of shrink wrap not only looks great as packaging, but it also helps with marketing. Companies can help increase and spread brand awareness by using printed materials within these package units. Read More…

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong is the world's leading manufacturer of automated, open-mouth bag packaging and closing systems and equipment. We offer a wide range of filled bag sewing machines, automatic bag heat sealers, robotic bag palletizers, bag making machines and semi-automated and automated bag packaging equipment that weigh, pack, close, check weigh, distribute, and palletize.

Trust Frain Industries for all your packaging equipment! We offer a variety of packaging equipment including stretch wrapper machines, filling machines, wrappers, shrink wrap machines, and more! We guarantee that all Frain machines will work for you so that you can work less!

TopTier is the preferred vendor for over 800 consumer packaged goods manufacturers with sales throughout North America and select countries worldwide. TopTier manufactures palletizers exclusively and serves both Fortune 1000 and mid-size companies. Contact us today for more information!

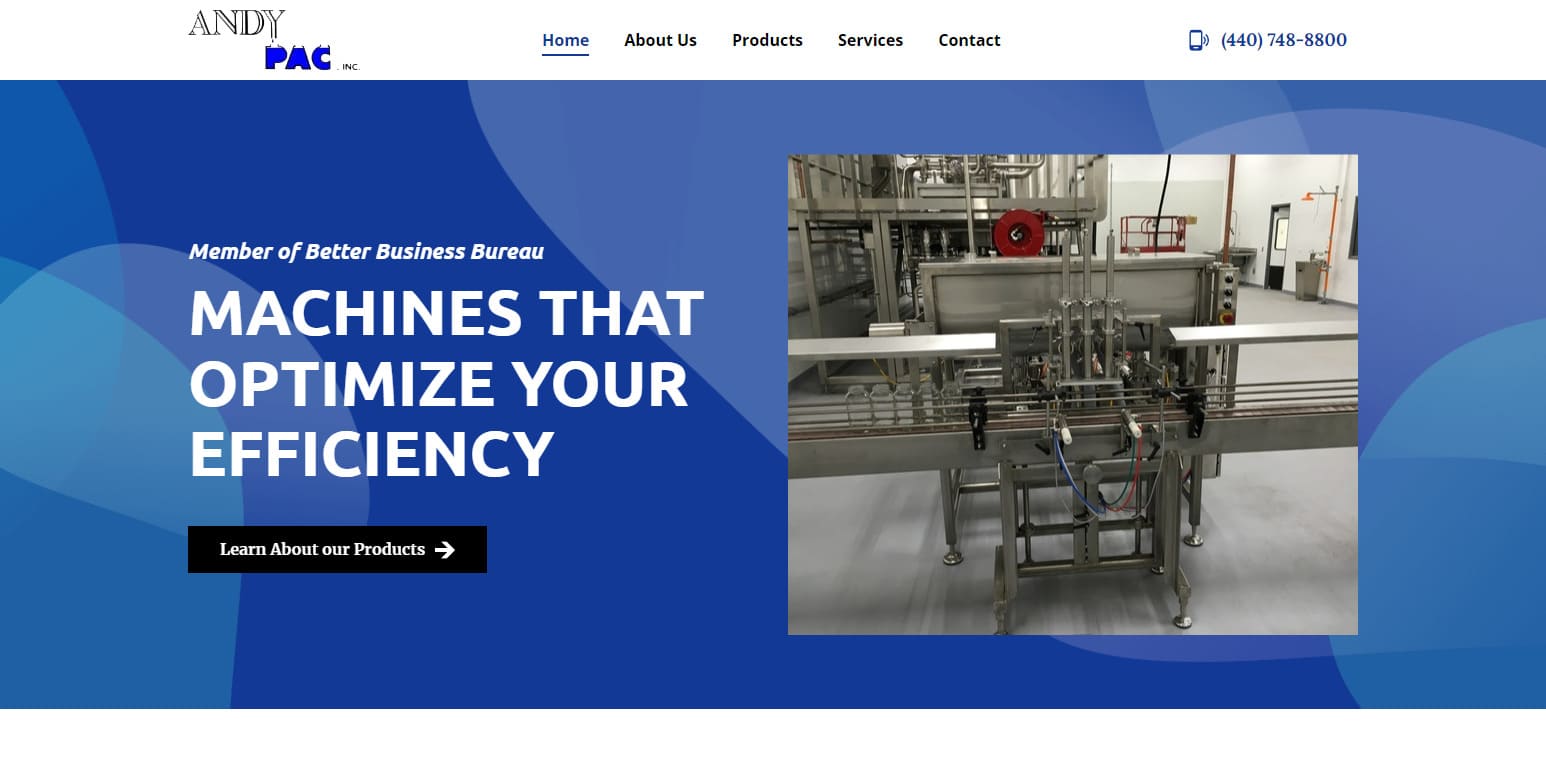

At Andy Pac, Inc., we specialize in delivering high-quality packaging machinery that meets the evolving needs of industries across various sectors. With a strong commitment to innovation, we design and manufacture equipment that enhances productivity, efficiency, and reliability in packaging operations. Our solutions are built to handle the demands of modern production lines, providing seamless...

More Shrink Wrap Machine Manufacturers

How the Shrink Wrap Machine Operates

The operation of a shrink wrap machine is simple and straightforward. An object is placed in the machine, and a loose film of shrink wrap is wrapped around it. The film is then tightly sealed around an item using heat. The end product is a clear, sparkling film that has been wrapped around the object. Because it is safer and stronger than stretch wraps or overwraps, shrink wrapping is frequently favored. It also conforms to the shape of the object more accurately than other wraps by generating a thin, translucent layer of plastic on top.

Types of Shrink Wrap(ping) Machines:

Reel Shrink Wrap Machine

With a reel shrink wrapping machine, a single reel of film is stretched and cut to length before being wrapped around the product. With this machine, film is loaded into a conveyor, then the product is fed onto the film. A portion of film is then cut from the roll and wrapped over the items before being sealed and heat shrunk. This method is especially beneficial for multipacks and packs that use printed film and require precise positioning of the printed area on the final product.

Twin-Reel Shrink Wrap Machine

Twin-reel shrink wrapping machines use two rolls of film simultaneously to provide a strong wrap for packaged products. They are the best option for large products (e.g., pallets, doors, and multipacks of large items), as this method can finish each product faster and with a stronger result than a single-reel shrink wrapper. Twin-reel shrink wrappers are ideal for low- to mid-speed output on products with simple packaging requirements.

L-Shear Shrink Wrap Machine

The L-shear shrink wrap model is designed to accommodate larger sizes of shrink-wrapping material. This machine has two sealing bars that form a backward 'L' shape. Shrink film bends down the two bars, creating a pouch-like opening through the folds that allows objects to pass through. Once the object is safely placed inside its pouch, the shrink film is then tightly sealed along the three other sides. The L-sealer can detect when an item has been completely inserted into the machine and when it is time to coat the objects with shrink film. Later, in the manufacturing line, a shrink tunnel grabs the unheated part of the shrink wrap attached to each product and warms it up so that it can fit snugly around each item.

Side-Seal Automatic Shrink Wrap Machine

In a side-seal automatic shrink wrapping machine, the items are wrapped in a continuous pipe of film which covers one side of the item before splitting into separate units downstream by a crisscross seal. Side sealers are typically found in two configurations consisting of either two or three belts. Two-belt shrink wrap machines work with the side seal being made after the cross seal. Some disadvantages of this machine include the constant need to ensure the products being wrapped are properly separated before being wrapped and that one may experience several breaks of the wrap material.

This type of shrink wrap machine is the most efficient when there is a need to wrap large items but don't have time to expand the production line. Sealers with three belts, on the other hand, are slightly larger than sealers with two belts and have the advantage of precisely spacing the items through an auto-space feature before they enter the area where they will be wrapped up. Three-belt shrink wrap machines feature three independently-operated belts which provide greater flexibility in packaging options. These machines work well with taller or shorter items than two-belt machines since the film isn’t pulled to form a cross seal around an item.

Importance of Shrink Wrap in the Packaging Industry

- Protection: Products are protected by shrink wrapping. Shrink wrap shields goods against tearing, dust, rubbing, and water damage. After wrapping the product in shrink wrap, one simply needs to seal the ends to produce a complete package. Then, heat the wrap to make it adhere to the item.

- Durability: Products are shielded from friction in palletized loads by shrink wrap. It forms a sturdy barrier to keep things safe while they are shipped from warehouses or directly to clients because no dirt or moisture can get inside.

- Tamper-resistance: This is yet another factor in why companies utilize shrink wrapping. Shrink-wrapped products might be taken directly from a business’ shelves before being sold or delivered to the customer. This packaging provides both parties with immediate proof if there has been tampering. As a result, it gives customers confidence in their purchases.

- Convenience: Shrink wrapping can be used on a wide range of products in terms of sizes and shapes. It can protect any size of product and cover objects with unusual shapes.

Design Considerations for Selecting a Shrink Wrap Machine

- Shrink film: There are two main types of shrink films which are polyolefin shrink film and PVC (polyvinyl chloride) shrink film. The polyolefin shrink is frequently used for both edible and non-edible products. It has fewer odors, a stronger seal, and more storage flexibility when sealing. The PVC shrink film is mainly used as an extra layer of packaging for non-edible products with solid containers and is mostly compatible with automatic machines. PVC shrink film is also typically used as pallet wrap.

- Product size: Another factor to consider is the size of the products being wrapped. Your shrink wrapping machine should be able to accommodate your largest products, because a larger machine will do smaller products as well. Your products’ length, width, and height and any additional packaging must all be considered when determining the appropriate size of your shrink wrap machine.

Choosing the Correct Shrink Wrap Machine Manufacturer

To ensure you have the most positive outcome when purchasing a shrink wrap machine from a shrink wrap machine manufacturer, it is important to compare several companies using our directory of shrink wrap machine manufacturers. Each shrink wrap machine manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each shrink wrap machine business using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple shrink wrap machine companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

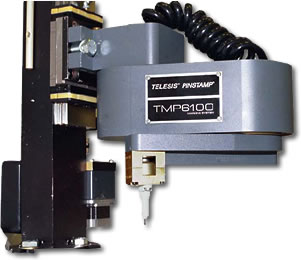

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services