Packaging equipment forms the backbone of modern manufacturing, warehousing, and logistics operations by automating the crucial processes of protecting, handling, and preparing products for storage, sale, and distribution. From the smallest retail items to large industrial goods, packaging machinery ensures that products remain safe, market-ready, and efficiently managed throughout their journey from factory to consumer. As companies seek to optimize productivity and minimize costs, the role of state-of-the-art packaging equipment—including automated packing lines, filling machines, case packers, sealers, and labeling solutions—becomes increasingly indispensable.

Often referred to as packaging machinery, this technology suite is essential in streamlining packing and shipping workflows, boosting operational efficiency, and reducing manual labor expenses. By automating repetitive tasks and ensuring product consistency, packaging equipment supports a wide range of industries—including food and beverage, pharmaceuticals, cosmetics, electronics, agricultural products, and consumer goods—while enhancing quality control and regulatory compliance.

But what exactly is packaging equipment, and how do you choose the best solutions for your business? Whether you are exploring how to automate your warehouse, searching for the right equipment for food safety regulations, or comparing packaging machine manufacturers, this guide provides in-depth answers and actionable insights to help you make informed decisions.

What is Packaging Equipment? Key Functions and Use Cases

Packaging equipment refers to a broad array of mechanical and automated machinery designed to enclose, seal, label, and protect products for distribution, storage, and retail sale. The primary function of packaging machines is product protection—shielding items from physical impact, temperature extremes, humidity, dust, and contamination. However, packaging also serves critical secondary purposes:

- Facilitating transport and handling: Packages make products easier to move within a facility and during shipping.

- Extending shelf life: Especially vital for food packaging, advanced sealing and vacuum systems help prevent spoilage and contamination.

- Enhancing product presentation and branding: Labeling and wrapping improve consumer appeal and ensure regulatory compliance for ingredient or safety disclosures.

- Improving storage efficiency: Well-designed packaging allows for compact, organized storage, reducing warehouse space requirements and operational costs.

For example, food packaging machinery specifically addresses the unique challenges of handling powders and perishable goods, automating the precise filling, sealing, and labeling of items like sugar, flour, dairy, and prepared meals. Similarly, pharmaceutical packaging equipment must comply with stringent safety and traceability requirements, ensuring tamper-evident seals, accurate dosing, and clear batch coding. In electronics and industrial manufacturing, packaging machinery protects sensitive components from moisture, static, and mechanical damage.

Looking for industry-specific applications? Explore:

- How is packaging equipment used in food processing and safety?

- What are the compliance standards for pharmaceutical packaging machinery?

- Which packaging solutions are best for electronics or industrial parts?

History and Evolution of Packaging Machinery

The evolution of packaging machinery reflects broader innovations in manufacturing, automation, and material science. Early packaging methods were entirely manual, relying on natural materials such as wood, animal skins, leaves, and woven baskets for containment and transport. As trade expanded and consumer markets grew, packaging technology evolved to meet increasing demands for product safety, convenience, and branding.

In the late 19th and early 20th centuries, the industrial revolution spurred the creation of new packaging types and the development of mechanized systems. Landmark inventions include:

- The first pouch machine (1894, Friedrich Hesser): Revolutionized the packaging of bulk goods by automating the formation and filling of flexible containers.

- The rotary bottle-making machine (1890, Michael Owens): Enabled mass production of glass containers, transforming the beverage and pharmaceutical industries.

- Introduction of plastics (early 1900s): Packaging machinery adapted to new materials, leading to lighter, more versatile, and cost-effective packaging solutions.

Post-World War I, rapid advancements in automation, printing, and material handling further expanded packaging capabilities. The invention of flexography (late 1920s) improved the accuracy and efficiency of packaging print, while the rise of cardboard and metal containers offered new options for product protection and branding. By the mid-20th century, packaging engineering became a recognized academic discipline, reflecting the critical role of packaging technology in global commerce.

Today, most packaging equipment is highly automated, leveraging computer-aided design (CAD), computer numerical control (CNC), robotics, and advanced sensor systems for unparalleled speed, accuracy, and flexibility. The industry’s current focus is on sustainability—developing eco-friendly materials and energy-efficient machinery that minimize environmental impact while maintaining safety and performance.

Benefits of Investing in Modern Packaging Equipment

Why should businesses invest in advanced packaging machinery? The advantages are compelling and span operational, financial, and strategic dimensions:

- Operational Efficiency: Automated packaging lines eliminate bottlenecks, reduce manual handling, and accelerate throughput. CAD and CNC-enabled machines streamline complex packaging tasks and enable rapid retooling for new product lines.

- Cost Savings: By reducing labor requirements and minimizing material waste, packaging equipment delivers a rapid return on investment. Features like automated weight checks, precise filling, and consistent sealing also prevent costly rework and product loss.

- Quality and Consistency: Precision-engineered machinery ensures every package contains the correct product amount, is properly sealed, and meets strict quality standards—vital for brand reputation and regulatory compliance.

- Worker Safety: Automating repetitive or hazardous packaging tasks lowers the risk of workplace injuries, fostering a safer environment and reducing insurance costs.

- Scalability and Flexibility: Modular equipment can be upgraded or reconfigured to handle new packaging formats, product sizes, or production volumes, supporting business growth and market expansion.

- Sustainability: Modern machines support recyclable, biodegradable, and lightweight packaging materials, helping companies meet sustainability goals and appeal to eco-conscious consumers.

Curious about how packaging machinery can transform your operations? Use our Packaging Equipment Buying Guide to assess your needs and compare solutions.

Types of Packaging Machinery: Functions, Applications, and Decision Factors

Packaging equipment comes in many forms, each tailored to specific tasks within the packing and shipping workflow. Whether you’re packaging liquids, powders, solids, or fragile goods, there’s a specialized solution to match your requirements. Below, we break down the most common types of packaging machinery, their primary applications, and decision points for buyers:

- Case Packing Equipment: Case packers automate the process of packing products into boxes or cartons. Available as top-load, side-load, and robotic systems, these machines are essential for manufacturers with high-volume output. Integrating with case sealers and palletizers, case packers ensure consistent, secure, and efficient packaging for everything from consumer goods to industrial parts.

- Filling Machines: Filling machines dispense precise quantities of product—liquid, powder, granular, or solid—into containers. Common types include volumetric, gravimetric, auger, and piston fillers. Specialized variants such as form-fill-seal (FFS) machines offer continuous production by forming containers from rollstock, filling them, and sealing in a single automated cycle. Filling machines are indispensable in the food, beverage, chemical, and pharmaceutical sectors.

- Labeling Equipment: Label applicators affix product identification, compliance information, barcodes, and branding labels to packages. Options range from fully automated high-speed lines for large manufacturers to compact, portable systems for small businesses. Choosing the right labeling machine depends on label size, adhesion method (pressure-sensitive, heat-activated), and production volume.

- Laminating Machines: Used to apply protective films to products, documents, and packaging materials, laminators enhance durability and presentation while safeguarding against wear, moisture, and handling damage. Industrial laminating machines can process high volumes, while desktop models serve offices and print shops.

- Sealing Machines: Sealing equipment ensures packages are closed securely and protected from environmental contamination. Heat sealers (including impulse and continuous band types) are popular in food packaging to maintain freshness. Medical and pharmaceutical applications often require validated sealing for sterility assurance.

- Shrink Packaging Machinery: Shrink wrappers apply a heat-sensitive plastic film that contracts tightly around products, providing tamper evidence, bundling, and aesthetic appeal. Used for everything from food trays to electronics, shrink packaging systems are available in fully automated, semi-automatic, and manual configurations.

- Strapping Machines: Strapping machines secure packages or pallets with bands, typically made from polypropylene or polyester, to facilitate safe transport and storage. They are essential in logistics, warehousing, and shipping environments.

- Vacuum Packaging Machines: Vacuum sealers remove air from packages before sealing, extending shelf life for food, pharmaceuticals, and sensitive electronics. Industrial models integrate with automated lines for high-speed production.

- Heat Sealers: These machines use heat to fuse thermoplastic materials together, creating airtight seals. Hot air sealers are ideal for continuous bag sealing, while impulse sealers offer manual or foot-operated control for smaller runs or varied bag sizes.

- Air Packers: Employing pressurized air, air packers quickly fill bags with fine powders or granular products—ideal for cement, sand, or powdered chemicals.

- Auger Packers: Utilizing auger screws to feed materials into bags, these machines excel at handling fine, flowable powders like flour, sugar, and powdered milk.

- Bagging Machines: Bagging machines automate the insertion of products into bags and subsequent sealing, offering speed, consistency, and reduced labor costs for a variety of industries.

- Food Packaging Equipment: Designed for compliance with food safety regulations, these machines automate the hygienic packaging of perishable and non-perishable food items, reducing contamination risk and improving shelf stability.

Key Questions to Guide Your Packaging Machinery Selection

- What type of product are you packaging (liquid, solid, powder, fragile, perishable)?

- What is your required production throughput (units per minute/hour)?

- Does your industry require compliance with specific safety or hygiene standards?

- What packaging materials will you use (paper, plastic, film, glass, metal)?

- How much floor space is available for new equipment?

- Do you need integration with existing automation or ERP systems?

Essential Features and Capabilities: What to Look For

When evaluating packaging equipment, consider the features that align with your operational needs and future growth plans. Here are important factors to assess:

- Automation Level: Choose between fully automatic, semi-automatic, or manual systems based on your labor resources and production volume. Automatic machines require minimal operator intervention and excel in high-volume environments.

- Speed and Throughput: Measured in Bags Per Minute (BPM) or packages per hour, ensure the machinery meets or exceeds your production targets.

- Sealing Technology: Evaluate seal quality (bead, heat, impulse), durability, and appropriateness for your packaging materials. Consider the impact of temperature, pressure, and dwell time on seal integrity.

- Versatility and Flexibility: Opt for equipment that accommodates multiple product sizes, shapes, and packaging formats. Features like adjustable mandrels, modular changeovers, and programmable settings increase adaptability.

- Mobility: Casters and compact footprints allow for easy relocation, essential for facilities with limited space or frequent production changes.

- Integration and Coding: Look for options to integrate with coding/marking systems (emboss or ink coders) for date codes, batch numbers, and regulatory compliance.

- Material and Consumable Management: Assess magazine capacity, ease of material replenishment, and the availability of wear parts and consumables for ongoing maintenance.

- Accuracy and Quality Control: Features like load cells, gross/net weight scales, and automated error detection help maintain production quality and reduce waste.

- Packaging Process Methods: Consider if your operation requires shrink-wrapping, stretch-hooding, or stretch-wrapping for additional load stability and product protection.

Want to compare packaging equipment features side-by-side? Request quotes or product demos from leading manufacturers to see which solutions best match your requirements.

Safety & Compliance Standards: Ensuring Reliable and Legal Packaging

Compliance with international and domestic safety standards is critical in selecting packaging equipment. Standards ensure machinery operates safely, reliably, and in accordance with regulatory requirements. Key standards to consider include:

- ISO 55.200: Covers a broad range of packaging machinery, including labeling, filling, marking, and sealing devices, ensuring international consistency and safety.

- ANSI (American National Standards Institute): Offers voluntary standards for non-retail packaging equipment, focusing on safety, performance, and reliability.

- Industry-Specific Standards: Food, pharmaceutical, and medical packaging often require compliance with FDA, GMP, or other specialized regulations for traceability, hygiene, and tamper evidence.

Check with your regional regulatory bodies to identify required certifications for your industry and export markets. Ensure your chosen machinery provider offers documentation and support for compliance audits.

Buying Guide: How to Choose the Right Packaging Machinery

Choosing the ideal packaging equipment for your business involves careful consideration of your product type, production volume, regulatory requirements, and budget. Here’s a step-by-step approach to guide your decision:

- Define Your Packaging Needs: List your product specifications, packaging format, volume targets, and any unique handling or compliance requirements.

- Research Manufacturers and Suppliers: Start with reputable companies—see the list at the top of this page—to compare equipment options, capabilities, and service levels. Visit their websites for detailed product descriptions, case studies, and customer testimonials.

- Request Quotes and Demonstrations: Reach out to multiple vendors and request live or virtual demos to see the equipment in action. Ask for references and inquire about after-sales support, spare parts availability, and warranty terms.

- Compare Pricing and Delivery: Evaluate total cost of ownership, including initial investment, maintenance, training, and expected lifespan. Consider lead times for new equipment and installation support.

- Assess Customer Service: Choose suppliers that offer responsive customer support and are committed to helping you meet your operational goals.

- Consider Pre-Owned Equipment: For budget-conscious buyers, high-quality pre-owned packaging machinery can offer significant savings and immediate availability. Ensure any used equipment is thoroughly inspected, serviced, and, if necessary, customized for your application.

Still have questions? Ask yourself:

- How will this equipment integrate with existing production lines?

- What training and technical support does the vendor provide?

- Does the solution allow for scalability as my business grows?

- How do I ensure continuous compliance with changing industry regulations?

For more information, visit our directory of leading packaging machinery manufacturers or contact us to request personalized recommendations based on your unique needs.

Trends and Innovations in Packaging Equipment

The packaging machinery industry continues to evolve rapidly, driven by advances in automation, sustainability, and digital integration. Key trends include:

- Smart Packaging Machinery: Integration with IoT sensors and cloud analytics enables real-time monitoring, predictive maintenance, and remote troubleshooting.

- Eco-Friendly Packaging Solutions: Machines designed for recyclable, compostable, or reusable packaging materials help companies meet environmental targets and consumer expectations.

- Flexible, Modular Designs: Equipment that adapts quickly to changing product lines, packaging formats, or production volumes maximizes ROI and minimizes downtime.

- Robotics and Vision Systems: Automated pick-and-place robots and camera-based inspection systems improve speed, accuracy, and product quality.

- Digital Printing and Customization: On-demand labeling and printing capabilities enable personalized packaging and rapid compliance with new regulations or market demands.

Interested in the future of packaging automation? Explore which innovations could add value to your operation.

Frequently Asked Questions About Packaging Equipment

- What are the most common types of packaging machines for small businesses?

Entry-level solutions like semi-automatic bagging machines, benchtop sealers, and portable label applicators provide affordable automation for low to moderate production volumes. - How do I calculate the ROI of new packaging machinery?

Factor in labor cost savings, increased throughput, reduced product loss, improved quality, and potential for business growth. Request a cost-benefit analysis from your supplier. - Can packaging equipment handle multiple product sizes and formats?

Many modern machines offer adjustable settings, tool-less changeovers, and programmable logic controls to accommodate a wide range of products. - How do I maintain and service packaging equipment?

Follow the manufacturer’s recommended maintenance schedule, keep an inventory of consumable and wear parts, and ensure staff are trained on routine upkeep and troubleshooting. - What safety features should I look for?

Emergency stop buttons, safety interlocks, guarding, and compliance with recognized standards (ISO, ANSI) are essential for safe operation.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

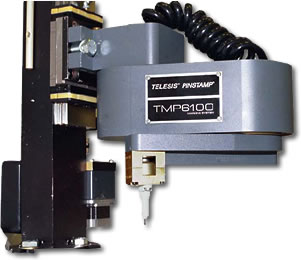

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services